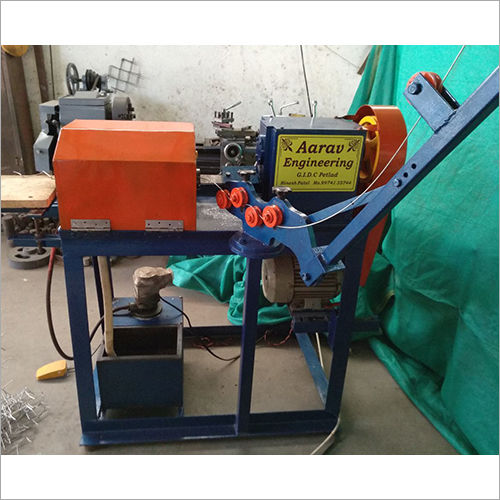

Get The Best Wire Crimping Machine, Barbed Wire Making Machine And More From The Best Company Of The Domain!!

Our Flexible Manufacturing System

In this modern world, the demands of buyers change with the changing time. With emerging trends in the market, they want newer and better products. This being the reason; we own a flexible manufacturing system. The implementation of the mentioned system helps us in manufacturing our product-line as per the requirements of our customers. It adapts well with the changing needs of the clients and functions accordingly. Besides, we enhance our operational flexibility by executing all the manufacturing tasks using varied products designs in smaller quantities and rapid delivery of produced goods at the customers' end. Currently, application of flexible manufacturing system increases the possibility of manufacturing products in different manners and ways for creating a competitive advantage.

Implementation of Total Quality Management

Total Quality Management (TQM) is an approach that we follow in our business for improving our internal processes, be it the production process or packaging process or material sourcing process. It has allowed us in achieving maximum client satisfaction because based upon this only we have been able to offer oru clients quality machines that work smoothly and without any trouble. The implementation of TQM has allowed us to understand the following:

In this modern world, the demands of buyers change with the changing time. With emerging trends in the market, they want newer and better products. This being the reason; we own a flexible manufacturing system. The implementation of the mentioned system helps us in manufacturing our product-line as per the requirements of our customers. It adapts well with the changing needs of the clients and functions accordingly. Besides, we enhance our operational flexibility by executing all the manufacturing tasks using varied products designs in smaller quantities and rapid delivery of produced goods at the customers' end. Currently, application of flexible manufacturing system increases the possibility of manufacturing products in different manners and ways for creating a competitive advantage.

Implementation of Total Quality Management

Total Quality Management (TQM) is an approach that we follow in our business for improving our internal processes, be it the production process or packaging process or material sourcing process. It has allowed us in achieving maximum client satisfaction because based upon this only we have been able to offer oru clients quality machines that work smoothly and without any trouble. The implementation of TQM has allowed us to understand the following:

- Quality cannot be achieved overnight, it is a continuous process to be worked upon

- Quality is not a rocket science to understand, it can be easily managed

- Processes we follow can sometimes be a problem

- Application of quality procedures is a long run investment

|

AARAV ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |